Your future is created by what you do today!

Courses Offered

B. Tech - Robotics and Automation

The Department of Robotics and Automation started the Bachelor of Technology programme in Robotics and Automation in the year 2020 with an intake of 60 students

About the Department

Department of Robotics and Automation is introduced from the Academic Year 2020-21 with a UG program of intake capacity of 60. This program is approved by AICTE, New Delhi and Affiliated to the APJ Abdul Kalam Technological University. The department has the ideal mix of faculty members with industry experience to produce future industry-ready engineers. Because of the present scenario toward digital manufacturing and industry 4.0, the Robotics and Automation curriculum addresses the demands of industries to efficiently equip their facilities to face global competitiveness. To outperform competition, every manufacturing company must lower manufacturing costs and lead times by introducing new technologies, which necessitates automation at every stage of the manufacturing process. Despite the ongoing trend toward automation and continued innovative technical developments in industrial robots, demand for industrial robots has increased significantly.

Automated system design, robot kinematics and dynamics, motion planning, Artificial Intelligence, machine vision, and Industrial Automation and Control are among the topics covered in this curriculum. The Department of Robotics and Automation Engineering was established to produce trained engineers in the field of industrial automation engineering. Industrial automation engineering is a cross-sectional discipline that necessitates sound, proportional knowledge in both hardware and software technologies, as well as their applications. This one-of-a-kind curriculum is designed to train excellent automation engineers for a variety of industries, including manufacturing, defence, agriculture, aviation, and other services.

Vision

To be a pioneer in robotics and automation education and create distinguished and ethical leaders committed to the profession and society via quality education, research and development.

Mission

- To provide students with opportunities to become leaders in robotics and automation education and research by facilitating learning, exposure, and skill.

- To provide a high-quality education that will result in graduates who are both professional and socially committed.

- To instil long-term skills in automation technologies, research and learning mindsets, and societal values in students.

Programme Educational Objectives

- Graduates will have a basic and deep understanding of various engineering concepts in order to build, analyse, and develop systems to solve real-world challenges using Robotics and Automation.

- Graduates are equipped with cutting-edge technology to design and build unique solutions using current tools, resulting in lifelong learning or improved skills, allowing them to become experts in their profession.

- Graduates will be trained in multidisciplinary technologies to support societal innovation, creativity, and entrepreneurship.

Programme Outcomes

Engineering Graduates will be able to:

- Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal,and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Programme Specific Outcomes

On the completion of Robotics and Automation program, the students will possess:

- An ability to analyse Automation systems/problems and recommend relevant technology for a more productive industrial ecosystem.

- An ability to Model, simulate, and design automation for increased industrial yield using engineering skills.

- An ability to explain and resolve problems in factory automation, create indigenous systems using current tools.

- An ability to develop robotics and automation engineering applications to solve human problems.

In India, robotics engineering is regarded as a high-end professional vocation. A candidate with professional skills in robotics engineering will have a plethora of work prospects. A robotic engineer can work in factories, labs, healthcare areas, mining, the robotics industry, biosciences, space applications, and agro engineering, among other places. If a candidate has a strong track record, they may be considered for top positions.

Aerospace industry

Flying robots, the clever bard robotic seagull, and the Raven surveillance drone are all included in this category of robots. This field is in high demand. In the aviation industry, the Future Scope of Robotics is in high demand.

Healthcare Sector

The use of robots in the medical field is still in its early stages. There is a fantastic future for increasing the number of robots used in clinical settings to conduct hard and long important jobs, as well as for healthcare system.

Manufacturing Sector

Such types of industrial robots are made up of manipulator limbs that can do any continuous operation. They can readily work with human employees.

Disaster response

Autonomous robots are employed to hunt for survivors in a disaster, and they can also track earthquakes, tsunamis, and nuclear power plants. The Emerging Scope of Robotics is Brighter in this Technology Field.

Education Sector

This is the next generation of robotics and board category for use in home and classrooms. This technology has to include hands-on the programmable sets From Lego and 3D printers with the lesson plans, and this type of robots can be able to replace any smart teacher.

Military and security

In India's military, machine learning and robotics are used in a variety of ways. India's defence, which is the world's fourth most powerful, is constantly updating and researching in terms of warfare and innovation.

Research

These robots can be valuable, but they must first and foremost be employed to assist researchers in doing what they do best: research and development.

Telepresence

These kinds of Telepresence robots can indeed be required to present at a location without physically visiting it. These robots are also capable of conversing with humans.

Space Research

Engineers that specialise in robotics can work for space research groups. It's a fascinating topic, and companies like the Indian Space Research Organization (ISRO) make substantial use of AI and robotic technologies. As a result, robotics engineering has a huge future in space research organisations like ISRO.

Consolidated Funded/Consultancy Work

| Sl.No | Year | Funding agency/Organization | Title | Investigators | Amount |

|---|---|---|---|---|---|

| 1 | 2021 | All India Council for Technical Education (AICTE) | Machinability evaluation and wear behaviour of hybrid Aluminium MMC reinforced with CNT and solid lubricants | Dr. Deepanraj B,Mr. Nice Menachery | 20,92,500 |

| 2 | 2022 | Kerala Development and Innovation Strategy Council, (K-DISC), Govt. of Kerala | Rejuvenation of handloom sector under ODOI scheme | Dr. Biju C. V,Mr. Praveen Raj | 4,57,000 |

| 3 | 2022 | Kerala Development and Innovation Strategy Council, (K-DISC), Govt. of Kerala | Studies on the characteristics of Eichhorniacrassipes as a source for bio fuel | Dr. Shaji James P. | 3,40,000 |

| 4 | 2022 | Centre for Engineering Research and Development (CERD), Govt. of Kerala -Student project | Development and testing of resonance free mechanical structures for enhanced stability in dynamic conditions | Dr. Biju C. V,Jobin C J,Edwin Anto ,Amal Paulson,Mariya Shobby | 45,000 |

| 5 | 2022 | Kerala Development and Innovation Strategy Council, (K-DISC), Govt. of Kerala | Performance enhancement of Thrissur traditional furniture cluster, Chovoor under ODOI scheme | Dr. Biju C. V,Mr. Jineesh K J,Mr. Anto Zacharias | 4,57,000 |

| 6 | 2022 | Adams Energy, Thrissur | Development of buoyant force based lifting Mechanism | Dr. Biju C. V,Mr. Christy V, Vazhappilly | 20,000 |

| 7 | 2022 | Kalyan Silks | CSR project on partial automation of traditional handloom systems | Dr. Biju C. V,Mr. Melvinraj C.R | 3,00,000 |

| 8 | 2022 | CERD, research seed money | Experimental investigation on thermal and physical properties of nano-enhanced phase change material for thermal management of electronic equipment | Mr. Anto Zachariah | 2 lakhs |

| 9 | 2023 | CERD, research seed money | Experimental investigation on thermal and physical properties of nano-enhanced phase change material for thermal management of electronic equipment | Mr. Anto Zachariah | 2 lakhs |

| Total: | 39,11,500 | ||||

Rejuvenation of handloom sector under ODOI scheme

Principal Investigator: Dr. Biju C.V.

Co-PI:Mr. Praveen Raj

Funding Agency: Kerala Development and Innovation Strategy Council, (K-DISC), Govt. of Kerala

Total Fund Sanctioned: Rs. 4,57,000

Scheme: One District One Idea (ODOI)

Status: On going

The Kerala Development and Innovation Strategy Council, (K-DISC) is a strategic think-tank and advisory body constituted by the Government of Kerala. In order to utilize the potential of Engineering Colleges in Kerala, KDISC introduced a programme called "One District One Idea" (ODOI) for the innovation of MSME clusters in the State. Under the scheme, Jyothi Engineering College, Cheruthuruthy has been identified as the mentor institution to rejuvenate the Handloom clusters in the Kuthampally area. The main objective of the project is to develop an action plan for the enhancement of productivity of the existing handloom units registered in the Kondazhy, Kuthampally, Eravathody and Thiruvilwamala Societies. More than 1000 units are registered under these four societies. Redefining the manufacturing process, introduction of new means for market and training centers for youngsters etc., will be the underlying focus of this project.

Machinability evaluation and wear behaviour of hybrid Aluminium MMC reinforced with CNT and solid lubricants

Principal Investigator: Dr. Deepanraj B

Co-PI: Mr. Nice Menachery

Funding Agency: All India Council for Technical Education (AICTE)

Total Fund Sanctioned: Rs. 20,92,500/-

Scheme: Research Promotion Scheme (RPS)

Status: On going

This research work is focused on preparation of a hybrid Nano metal matrix composite containing Aluminium as the matrix material and carbon Nano tubes and solid lubricant as reinforcement by powder metallurgy route. The mechanical behaviour of this hybrid Nano-composite is evaluated by means of tensile test, compression test, micro-hardness, corrosion test and wear test. The distribution of reinforced materials in the matrix is by SEM image. Machinability evaluation of the cast MMC is studied to determine the performance of the MMC during turning with an uncoated and coated cutting tool inserts.

Studies on the characteristics of “Eichhorniacrassipes” as a source for bio fuel

Principal Investigator: Dr. Shaji James P.

Funding Agency: Kerala Development and Innovation Strategy Council, (K-DISC), Govt. of Kerala

Total Fund Sanctioned: Rs. 3,40,000/-

Status: On going

Water hyacinth (Eichhorniacrassipes) is a monocotyledonous fresh water weed which is an aquatic macrophyte that has gained attention because of its fast growth, leading to serious problems in navigation, irrigation and power generation.It is a non-crop plant available in plenty and their growth characteristics make them an ideal candidate for biomass production.. Since biomass is produced from atmospheric carbon dioxide, it helps in sequestrating carbon and reduce greenhouse gas concentration in atmosphere. Water hyacinth can be used as a feedstock for generating biofuels. As there is a scope for energy production from water hyacinth, it is highly relevant to study the characteristics of water hyacinth biomass for production of biofuel.

Present Status

First phase of the study concluded.

Salient result: There is not much scope for production of biodiesel from water hyacinth biomass.

Ongoing studies: - Possibility of other routes for energy production, especially Anaerobic digestion.

Development and testing of resonance free mechanical structures for enhanced stability in dynamic conditions

Principal Investigator: Dr. Biju C.V

Co-PI: Jobin C J, Edwin Anto, Amal Paulson, Mariya Shobby

Funding Agency: CERD KTU

Total Fund Sanctioned: Rs. 45,000/-

Status: On going

In order to avoid resonance issues a tunable frequency mechanical structure is effectively designed in the proposed project. Based on the feedback, the smart system based on the piezo electric material, change the effective stiffness and there by natural frequency of the mechanical structure. The first phase of the project was completed and the preliminary trials gives positive result. In the second phase an attempt is made to reduce the response time and there by the resonance is avoided in the onset of unwanted vibration of the structure.

Performance enhancement of Thrissur traditional furniture cluster, Chovoor under ODOI scheme

Principal Investigator:Dr. Biju C.V.

Co-PI: Mr. Jineesh K J, Mr. Anto Zacharias

Funding Agency: Kerala Development and Innovation Strategy Council, (K-DISC), Govt. of Kerala

Total Fund Sanctioned: Rs. 4,57,000

Scheme:One District One Idea (ODOI)

Status: On going

The Kerala Development and Innovation Strategy Council, (K-DISC) is a strategic think-tank and advisory body constituted by the Government of Kerala. In order to utilize the potential of Engineering Colleges in Kerala, KDISC introduced a programme called "One District One Idea" (ODOI) for the innovation of MSME clusters in the State. Under the scheme, Jyothi Engineering College, Cheruthuruthy has been identified as the mentor institution to rejuvenate the Thrissur Traditional Furniture clusters in the Chovoor Villaege in Thrissur District. The main objective of the project is to develop an action plan for the enhancement of productivity of the esisting furniture units in the cluster and effective utilization of the Common Facility Center (CFC). More than 700 units providing direct employment of more than 3,000 people plays vital role in the financial stability of the village.

The objectives of the project comprises

- 1.To enhance the quality of the product by effective chemical treatment and seasoning.

- 2.To find out the feasibility of knock-down furniture to attract new customer segment.

- 3.To stream line the production line by effective analysis of the capacity available resources in the cluster with the market demand.

- 4.To carryout research activities to analyze the characteristics of finger joints.

Development of buoyant force based lifting Mechanism

Principal Investigator:Dr. Biju C.V.

Co-PI: Mr. Christy V. Vazhappilly

Funding Agency: Adams Energy, Thrissur

Total Fund Sanctioned: Rs. 20000/-

Type::Industrial consultancy

Status:On going, MoU signed and preliminary phase completed

The advantages of the buoyant force in the constraint volume are investigated in the project. The theoretical background of Archimedes principle as well as flow against drag is extensively analysed.

CSR project on partial automation of traditional handloom systems

Principal Investigator:Dr. Biju C.V.

Co-PI: Mr. Melvinraj C.R

Funding Agency: Kalyan Silks, Thrissur

Total Fund Sanctioned:Rs. 3,00,000/-

Type::Corporate Social Responsibility (CSR) project

Status:On going

For the rejuvenation of handloom sector, M/s Kalyan Silk, Thrissur provided an amount of 3,00,000/- as part of their CSR fund. As a part of the fund a traditional hand loom has been set in the campus. The state Minister K Radhakrishnan who is also representing our Constituency, inaugurated the handloom training centre on 21 st Sept. 2022. Out of the 42 candidates applied for the handloom training, a group of 6 candidates were selected and their training is being scheduled from 19 th -29 th Sept. 2022. The partial automation of the traditional loom is designed and MoU for the professional support is planned with EMC automation, Thrissur.

-

Click on the news title to get the details...

-

Technical Talk on " How To Solve Technical Problems By Doing Technical Projects"

NDLI Club Jyothi Engineering College in Association with Department of ...read more

-

SARA - INAUGURATION

The technical talk was conducted in the Decennial Hall on ...read more

-

Signed MoU with M/s. Axis Global Automation

Department of Robotics and Automation, Jyothi Engineering college has signed ...read more

-

Invited Talk on Industrial Robotics

Invited talk on Industrial Robotics is conducted on 19th Aug ...read more

-

One day workshop on " Embedded programming"

Department of Robotics and Automation and IIIC of Jyothi Engineering ...read more

LIST OF EXPERIMENTS

All experiments from Part A, Part B and Part C are mandatory

Part A: Robotic Manipulators (3 DOF or greater) (All experiments mandatory)

1. Joint space and Cartesian space trajectory planning for a pick and place task

2. Obtain forward and inverse kinematic models (check end effector and joint positions with theoretical and actual values)

3. Point to point control and continuous path control

Part B: Mobile Robots

1. Control of mobile robot for moving to a point(xg, yg) , following a line (ax+by+c=0), moving to a specific target orientation (θg) (Closed loop control considering kinematic models)

2. Obstacle avoidance of a mobile robot while moving to a point.

3. Localization of a mobile robot using LIDAR

PART C: Sensor based experiments

1. Calibration of sensors-sonar, IR sensors and obtain the calibration curve

2. Object detection using any one standard algorithm

3. Object tracking and visual servoing

4. Following a moving target/ Object tracking from a moving vehicle

PART D: Mini Project (any one –compulsory)

1. Design and develop a servo controlled robotic manipulator (1 DOF) with visual feedback for pick and place task

1. Design and develop a mobile robot capable of obstacle avoidance and localisation

2. Assemble a quadcopter drone kit and make it hover.

- Faculty InCharge: MANIKANDAN N. R

- Phone Extention: 2147483647

List of Experiments

PART A

10 Experiments mandatory

1. Writing a Simple Publisher and Subscriber, Simple Service and Client,Recording and playing back data, Reading messages from a bag file(Python/C++)

2. Getting Started with Turtlesim

3. Familiarisation with Rviz -- Markers: Sending Basic Shapes -- use visualization_msgs/Marker messages to send basic shapes, to send points and lines (C++), Interactive Markers: Writing a Simple Interactive Marker Server, Basic Controls

4. Introduction to tf -- broadcast the state of a robot to tf, get access to frame transformations, Adding a frame, waitForTransform function, Setting up your robot using tf, publish the state of your robot to tf, using the robot state publisher.

5. Building a Visual Robot Model with URDF from Scratch, Building a Movable Robot Model with URDF, Adding Physical and Collision Properties to a URDF Model.

6. Familiarisation with Gazebo--How to get Gazebo up and running,Creating and Spawning Custom URDF Objects in Simulation, Gazebo ROS API for C-Turtle, Simulate a Spinning Top, Gazebo Plugin - how to create a gazebo plugin, Create a Gazebo Plugin that Talks to ROS

7. Create a Gazebo Custom World (Building Editor, Gazebo 3D Models), Add Sensor plugins like Laser, Kinect, etc. to URDF of mobile robot

8. Create a 3DOF robotic arm from scratch

9. Familiarisation with MoveIt through its RViz plugin, Motion Planning with the Panda or other robot models.

10. Create Moveit package for robotic arm simulation and add controllers,Plan a path for a 3DOF Robotic Arm and execute the same, Move the 3DOF arm to a desired goal point

11. Attach 2DOF gripper as the end effector of 3DOF arm and execute gripping operations, Execute Pick and Place Operation

12. Familiarisation with 2D navigation stack, Basic ROS Navigation, Start robots in simulation.

13. Execute SLAM Mapping (Lidar based) using a differentially driven mobile robot

14. Execute AMCL Navigation in a known environment using a differentially driven mobile robot.

PART B (Hardware experiments) (2 experiments mandatory)

15. Familiarise ROS Serial Arduino for hardware interface.

- Faculty InCharge: DR.JOBIN VARGHESE

- Phone Extention: 2147483647

-

Office Bearers

Chairman -Navaneeth Nalesh C J

Vice Chairman - Praveena M P

Secretary - Devadath P R

Joint Secretary - Vismaya Thankam John

Treasurer - Joshua Jose

-

Executive Members

1. Yadu Prasad N

2. Alvin Antony Jomon

3. Ameer Ali Khan

4. Aswin P Rathnan

5. Abhijith V S

6. Aswin K D

7. Joel Johnson

8. Bitto K B

9. Sudev Sunil

10. Adeeb Babu

11. Elvin Raphael

12. Adithya Dinesh Rao

-

Staff Incharge

Athira P Preman

-

Activities

The technical talk was conducted in the Decennial Hall on “Industrial Automation” organized by the Indian Society for Technical Education (ISTE), in association with Robotics and Automation’ Association (SARA) on 21st December 2022. The audience included staff & students of S1, S3, & S5 of RA.

The event started at 2:30 PM. with the welcome speech done by Dr. Karthik C (HOD) followed by the presidential address by Dr. Jose.P Therattil, (Principal). Thereafter technical session by Mr. Sivanesan. P founder & COO of Innovative Engineering Services, Chennai. The main focus was on current opportunities in Industrial Automation. The session continued till 4:00 PM. & Navaneeth Nalesh (Chairman )delivered the vote of thanks.

-

2023

CLASS TOPPERS - S4 UNIVERSITY EXAMINATION (BATCH 2020-2024)

RANK NAME OF STUDENT SGPA 1 POWRNAMI P 8.5 2 BITO K B 7.86 3 JOEL JOHNSON 7.05

-

2023

CLASS TOPPERS -S2 UNIVERSITY EXAMINATION (BATCH 2021-2025)

RANK NAME OF STUDENT SGPA 1 ASWIN DINESH RAO 8.12 2 ASWIN VINOD 7.31 3 ALAN GEORGE SHIBU 6.92

-

2023

Devadath P R(S6 RA) and Navaneeth Nalesh C T (S6 RA) participated and won first prize in Agri Hack 23 which is the Kerala's largest Agricultural Hackathon conducted by the Department of Agriculture Development and Farmers welfare, Govt. of Kerala, as part of the VAIGA Agricultural Fest from 25 th to 27 th February 2023.

-

2022

Mr. Navaneeth Nalesh & Mr. Devadath P.R. of S3 Robotics have ben selected to the final round of National Robotics Competition conducted by IISC, Banglore, under the guidance of Dr.C.Karthik . The team recieved grant of Rs. 4,00,000/- for the prototype developement.

-

2022

Mr.Aswin K.D and Mr.Navaneeth Nalesh received first prize in project competition “Shristi-22” for the project “ Firefighting Drone” competition and won Rs. 10000 cash awards organized by Jyothi Engineering College.

-

2022

CLASS TOPPERS -S2 UNIVERSITY EXAMINATION (BATCH 2020-2024)

RANK NAME SGPA 1 POWRNAMI P 8.67 2 BITO K B 7.55 3 JOEL JOHNSON 7.21

-

2022

CLASS TOPPERS - S3 UNIVERSITY EXAMINATION (BATCH 2020-2024)

RANK NAME SGPA 1 POWRNAMI P 8.64 2 PRAVEENA M P 7.41 3 JOEL JOHNSON 6.55

-

2022

CLASS

RANK NAME OF STUDENT SGPA 1 ADITHYA DINESH RAO 8.03 2 SAFA NASRIN S A 6.88 3 ASWIN VINOD 6.76 TOPPERS -S1 UNIVERSITY EXAMINATION (BATCH 2021 -2025)

-

2021

CLASS TOPPERS -S1 UNIVERSITY EXAMINATION (Batch -2020-2024)

Rank Name of Student SGPA 1 Powrnami P 9.94 2 Bito K B 7.65 3 Navaneeth Nalesh C T 7.29

-

2023

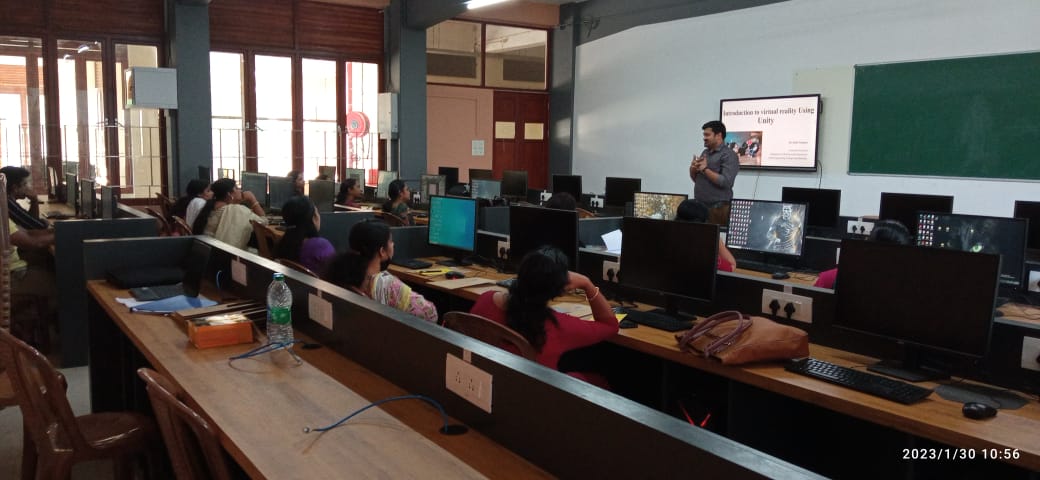

Dr. Jobin Varghese handled a session on "Introduction to Augmented and Virtual Reality" in KTU Sponsored 5 Day FDP organized by Dept. of Electronics and Communication Engineering, Christ College of Engineering, Irinjalakuda from 30 th January 2023 to 3rd February 2023

2022

Dr.Jobin Varghese presented an innovation titled Portable Rubber Sheet Dryer in the exhibition Category of Rural Innovators Meet 2022 organized jointly by Kerala State Council for Science Technology & Environment (KSCSTE) and ICAR -Central Plantation Crops Research Institute (CPCRI) during 25 th to 27 th November 2022 at ICAR -Central Plantation Crops Research Institute, Kasaragod.